Film-Based Negatives and Positives

The stability of the support (film base) is one of the most significant factors for long-term preservation of any film including photographic negatives, microforms, and motion picture film. Storage in cold temperatures (35°F or lower) is very important in preserving cellulose nitrate and cellulose acetate films regardless of format.

The three basic types of film supports are polyester, cellulose acetate, and cellulose nitrate. The date of manufacture for these film supports overlap each other, and supports were used for different formats at different times. Film stock was also used beyond the date of manufacture until it was depleted. This makes it difficult to identify the type of film support by date alone.

For information on a specific archival format, please click on the links below:

- Polyester Film

- Cellulose Acetate Film

- Cellulose Nitrate Film

- Photographic Negatives, X-Rays, and other Sheet Films

- Microfilm, Microfiche, and other Microforms

- Motion Picture Film

Polyester Film

Polyester was introduced in the mid 1950s but dates for its use vary for different formats. Generally, most sheet film from the 1970s onwards is polyester based. It has been the predominant base used for motion picture film since the 1990s.

- Polyester film is dimensionally stable and does not distort, break, or tear easily, unlike other film bases.

- Polyester film may have ESTAR (Kodak) or Chronar (Dupont) in the trade name.

- A polarization test can be used to identify polyester film; when viewed between two crossed polarizing filters, polyester produces rainbow-colored interference patterns.

- Polyester film reels often appear translucent with light passing through the film reel when the reel is held parallel to the eye.

Cellulose Acetate Film

Cellulose acetate film began replacing nitrate film in the 1920s and was predominantly used until the 1970s. Cellulose acetate and triacetate film is often identified by the word “SAFETY” printed along the edge. (Note that copied film will contain any edge printing that was present on the original which could lead to mis-identification).

Cellulose acetate film may be stable but is susceptible to acidic deterioration called “vinegar syndrome” at any point in time.

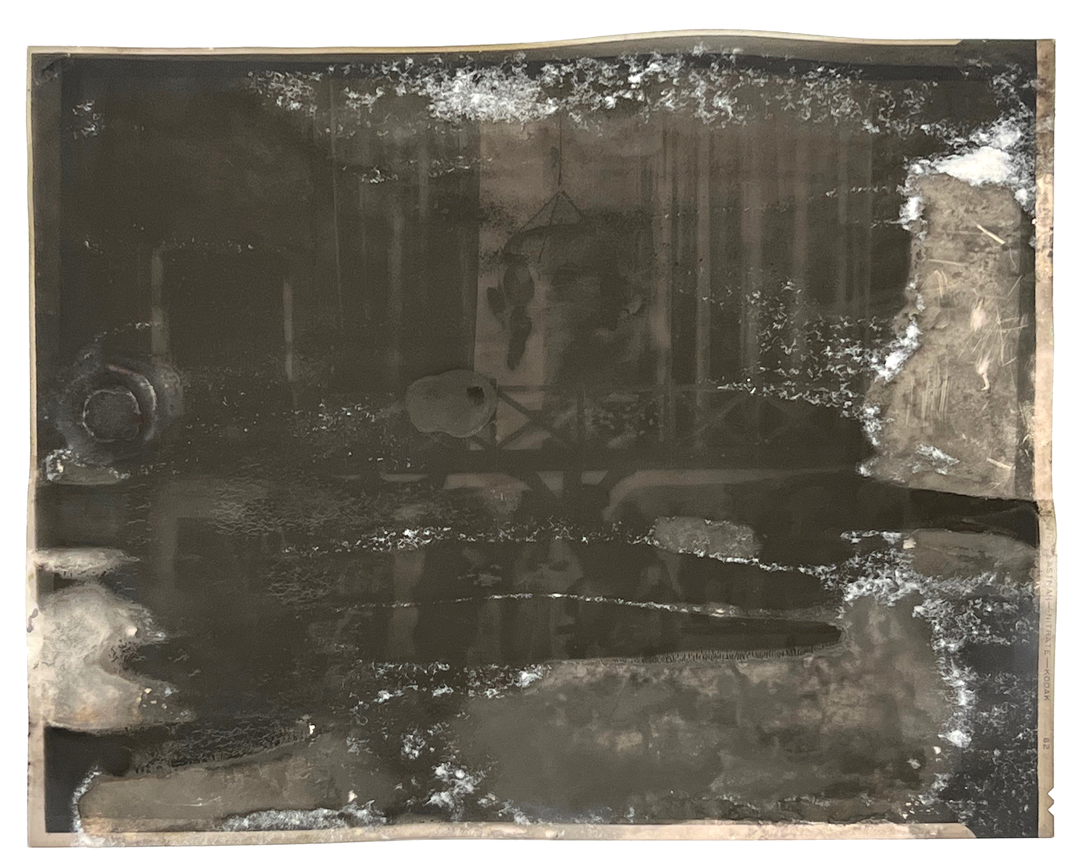

- This deterioration is initiated within the film, especially when stored in warm and high relative humidity conditions. Signs of deterioration include dimensional changes, crystals, bubbles, or channels forming brittleness, and most typically a strong odor similar to that of vinegar.

- Consider using A-D Strips (acid detection strips) from the Image Permanence Institute (IPI) to evaluate the degree of vinegar syndrome deterioration of acetate film. Results can aid holdings maintenance by identifying deteriorating films that should be prioritized for cold storage and/or reformatted.

- Isolate deteriorating film whenever possible to prevent the initiation of degradation in surrounding film; for example, store deteriorating film in a box separate from film in good condition.

- Prioritize the reformatting of deteriorating film.

- For additional information see the IPI Storage Guide for Acetate Film.

Consider cold storage for cellulose acetate holdings, including motion picture and still picture film negatives, aerial film, x-rays, microfilms and microforms, slides, and animation cells.

- Cold storage significantly decreases the chance of vinegar syndrome beginning, and once vinegar syndrome has begun, cold storage will dramatically slow down the acidic deterioration. Cold temperatures slow but do not stop cellulose acetate deterioration.

- Cold storage will extend the usable life of the film by many decades or centuries.

- Cold storage is especially important for cellulose acetate that is already showing any sign of deterioration and for highly significant, important holdings.

Cellulose Nitrate Film

Cellulose nitrate was the only film base available from the 1890s until the 1920s, and was produced until the early 1950s. Some nitrate film can be identified by “NITRATE” printed along the edge or by a “V” notch in the upper right corner when the emulsion is facing up (film in vertical/portrait orientation). (Note that copied film will contain any edge printing that was present on the original which could lead to mis-identification).

Handle and store cellulose nitrate film with extreme caution. It can be very unstable and deteriorate rapidly, especially in non-climate-controlled conditions.

Cellulose nitrate can pose a serious fire risk when stored improperly and therefore has specific storage requirements beyond temperature and humidity. Separate nitrate film from other records and follow guidelines in National Fire Protection Association (NFPA)40: Standard for the Storage and Handling of Cellulose Nitrate Film. Storage regulations are determined by the quantity (weight) of film. Small quantities of film may be able to be stored in flammable materials cabinets or flammable materials freezers rather than special vaults (refer to NFPA40 for specific regulations).

In the United States, there are also federal regulations for the transportation as well as disposal of nitrate film (see 36CFR, 40CFR and 49CFR).

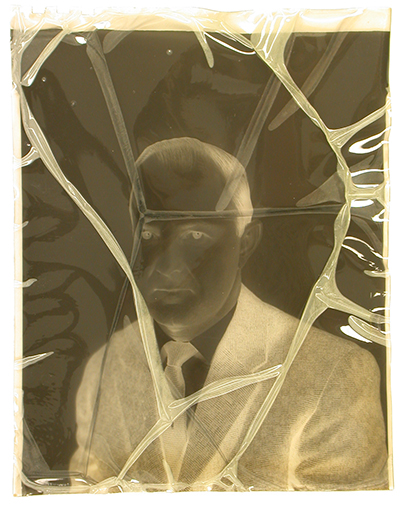

Signs of deterioration include image fading or silver mirroring, yellowing, tackiness, curling or brittleness of the film itself, and an acidic smell of nitric acid. For additional information see Library and Archives Canada’s A Visual Glossary of Six Stages of Nitrate Film Base Deterioration. Cold temperatures slow but do not stop cellulose nitrate deterioration.

- Nitrate film should be duplicated or digitized by a knowledgeable company or person specially trained to handle nitrate film.

- Deposit nitrate film with an institution capable of storing nitrate according to NFPA 40. If controlled storage is not possible, dispose of nitrate film according to federal regulations.

- Contact a conservator or preservation specialist for additional information and/or assistance if cellulose nitrate is identified in the collection.

Photographic Negatives, X-Rays, and Other Sheet Films

A variety of sheet film records such as photographic negatives, X-rays, and transparencies may be found in archival collections. Holdings maintenance guidance is similar for these formats.

Handle all sheet film records with gloves, avoiding the image area.

- If there is visible dust on the film, it can be brushed lightly with a clean, soft brush. A hand operated puff-style blower can also be used to reduce dust on photographic records. Canned air should be avoided due to the damaging force of the air stream and potentially damaging propellants.

Do not attempt to clean film with water-based solutions or other chemicals. Discuss options for cleaning with a photograph conservator or preservation specialist.

Sheet film may be polyester, cellulose acetate, or cellulose nitrate. Cellulose nitrate and cellulose acetate film have special requirements. See the sections on film base types and Cold Storage for more information.

Enclosures for Holdings Maintenance

Protect sheet film from scratches and abrasion by storing it in an enclosure.

- Existing enclosures may or may not be stable. Consider replacing older enclosures that are brittle, warping or otherwise showing signs of damage.

- When there is no enclosure or older enclosures are being replaced, house one negative, X-ray or other loose sheet film in an individual sleeve or envelope that meets NARA specifications and/or look for products that meet the requirements of ISO 18902: Imaging materials — Processed imaging materials — Albums, framing and storage materials and have passed the ISO photographic activity test (PAT) established in ISO 18916: Imaging materials — Processed imaging materials — Photographic activity test for enclosure materials.

- Use paper enclosures for negatives known to be or suspected to be cellulose nitrate or cellulose acetate.

- Negative emulsions are thin and susceptible to static electricity that can be generated by plastic enclosures. Use a paper folder or a four-flap paper enclosure to house a significant film with flaking emulsion. Store film with flaking emulsion horizontally.

- Office-quality products, plastics containing PVC and/or glassine enclosures are not recommended for records storage.

Avoid writing directly on the sheet-film, even along the edges. Write on the storage enclosure before the film is placed inside.

Store sheet film negatives, X-rays and similar records vertically whenever possible.

- Add a spacer board or filler board to hold the films upright and prevent bending or curling.

- Avoid overfilling a storage box or stacking boxes more than two high. Avoid stacking very heavy boxes.

- Remove negatives and slides stored in plastic sleeves in ring binders or hung in a file cabinet suspended by metal supports, when possible. Store vertically in an archival box that meets NARA specifications and/or that meets ISO 18902 and ISO 18916 standards.

Storage in temperatures at or below 35°F, referred to as cold storage, is recommended for acetate cellulose film (safety film), cellulose nitrate film, color film, and any film that is highly significant.

Microfilm, Microfiche, and Other Microforms

Several types of microfilm and microfiche have been manufactured using different base supports. Most microfilm supports will be either acetate or polyester. General guidelines for microfilm and microfiche follow.

Handle microfilm and microfiche by their edges only and wear gloves to prevent the transfer of oil and other substances from hands to the film.

Inspect the film for common types of degradation, particularly vinegar syndrome, distortion and redox blemishes for acetate films.

- If resources are available, assess the degree of acetic acid degradation, called "vinegar syndrome," of cellulose acetate using A-D Strips. If deterioration is detected, consider preservation actions (cold storage and/or reformatting) discussed in these pages.

- Consider prioritizing deteriorated film for reformatting and/or cold storage.

- Inspect film for redox blemishes, the yellow/red/orange spots in the image caused by silver oxidation.

- Consult with a preservation specialist or photograph conservator for additional preservation guidance for deteriorated microforms.

Consult a preservation specialist about splicing damaged film with approved splicing materials or an ultrasonic welder. Do not use scotch tape to repair broken film.

Maintain viewing and digitization equipment. Keep all equipment and surrounding work surfaces clean and free of dust to avoid scratching or abrading film.

Inspect microfilm reels for any damage. Consider replacing metal reels, especially if they show signs of rust or other deterioration, with archival plastic reels.

Some microfilm wound inside cartridges may not be accessible on available equipment. Consult with a preservation specialist or photograph conservator if film needs to be removed from cartridges for viewing or digitization.

Rolls of microfilm larger than a standard reel may be wound on plastic cores similar to those used for storage of motion picture film. Consult with a preservation specialist or conservator for handling and storage guidance as needed.

Evaluate the film to ensure there is sufficient leader at the beginning and ending of the film reel to facilitate threading through viewing and digitization equipment.

- At least three feet of leader (polyester film in the same dimension as the reel) is recommended at both the beginning and end of the reel.

- Clear polyester leader may be attached with approved splicing materials or ultrasonic welder.

- Replace any unprocessed microfilm leader with clear polyester leader. Unprocessed microfilm should not be used as a leader. Chemicals in unprocessed microfilm (often red or yellow in color) can damage the microfilm.

Store roll microfilm in low-lignin paper microfilm boxesor in chemically inert polyester, polyethylene, or polypropylene plastic boxes.

- Choose an appropriate size enclosure for 16mm or 35 mm film.

- Only house film in plastic boxes if the storage environment is controlled to prevent high relative humidity conditions. Moisture trapped inside the plastic enclosure can cause film to become blocked or deteriorate more rapidly.

- Store roll microfilm in the wound position. Avoid winding film too tightly to prevent emulsion damage.

- If needed, secure the wound film roll with a preservation quality string and/or button tie label as needed. Never use a rubber band to secure microfilms.

- Record information on the storage box or paper tie label.

Store individual strips of microfilm each in a plastic sleeve or microfilm jacket, or in a paper sleeve or envelope that is acid-free, lignin-free, buffered, and has passed the PAT (photographic activity test).

Store each microfiche sheet in a separate paper sleeve or envelope that is acid-free, lignin-free, buffered, and has passed the PAT (Photographic Activity Test).

- Use appropriately sized sleeves so that microfiche edges do not extend beyond the sleeve.

- Store sleeved microfiche vertically in low-lignin paper boxes or in file-type cabinets.

- Avoid packing the sleeved microfiche too tightly to prevent compression and to facilitate safe retrieval of a film.

- Use a spacer board to keep fiche upright and prevent slumping.

Cold storage is recommended for acetate and color microforms. Control moisture and maintain relative humidity below 50%. Keep microforms away from ionizing air cleaners or other sources of ozone.

Motion Picture Film

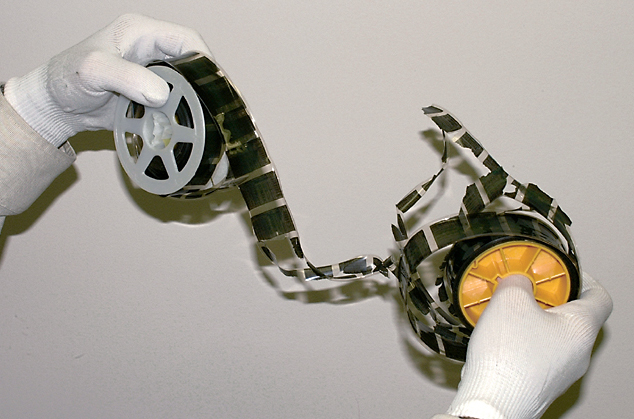

Many gauges and formats of motion picture film have been used since the late 1800s and their stability varies. Consult with a motion picture preservation specialist on longer-term preservation and reformatting of a specific film.

Handle motion picture film as little as possible.

- When you need to handle film, wear clean cotton gloves or clean nitrile gloves to prevent oils, salts, and other skin deposits from degrading the image over time.

- Handle by the film edges and avoid touching the surfaces, especially the emulsion (duller) surface, even when wearing gloves.

Damage is possible each time an original film is projected. It is preferable to use a copy of a motion picture film for researcher access and programs.

- Consider having films digitized or duplicated by a reputable vendor, especially those likely to be of high interest or significance.

For additional information on motion picture film, please refer to the links below: